Battery Organizing

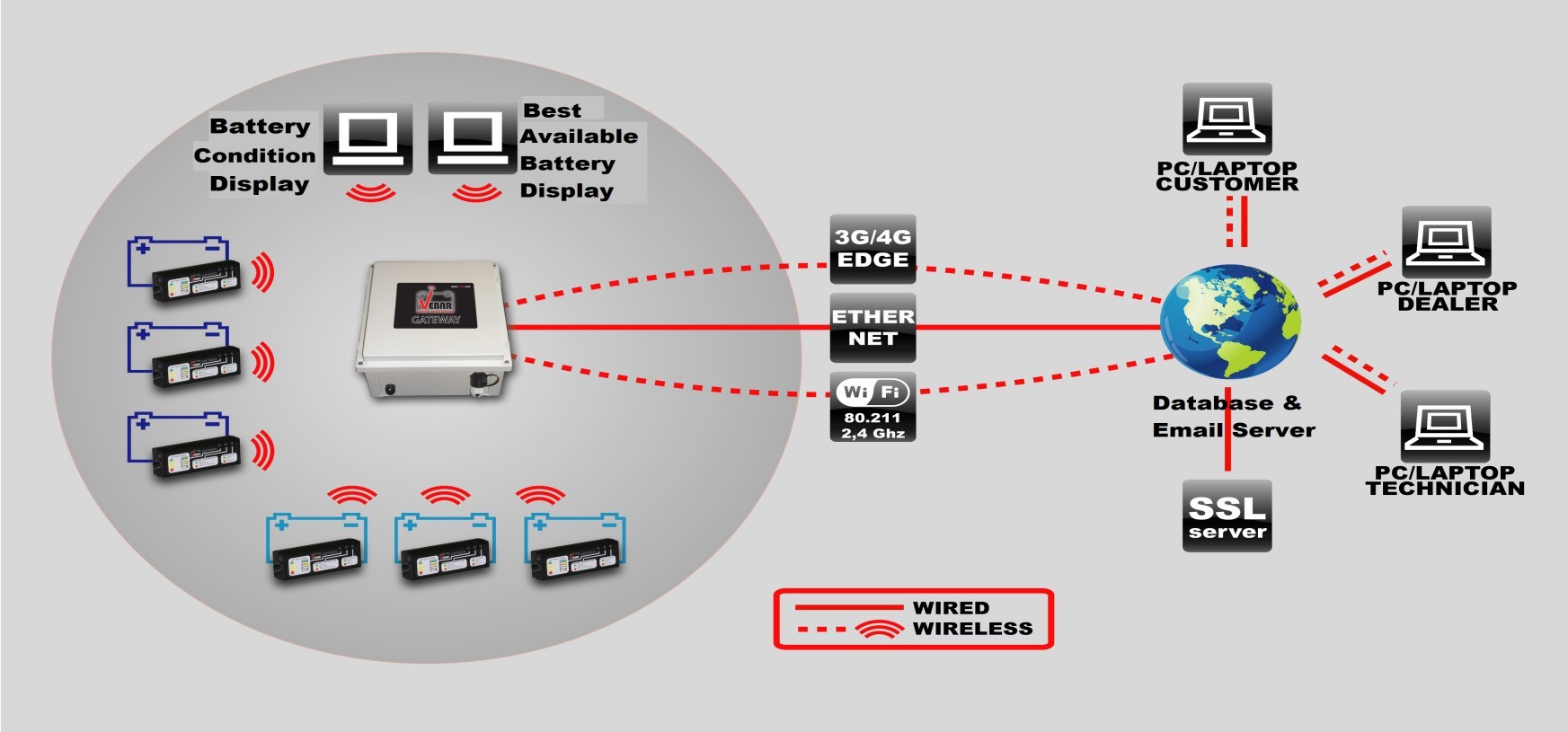

Wireless Battery Monitoring – System Components:

- Vebar® Battery sensors are installed on the batteries: for Automated 24-7 Battery Health

- Vebar® Best Available Battery Displays are installed in the charging room:

They inform the operator of the Best Available Batteries that have NO issues, are fully charged, cooled and ready to be used when forklifts come in for a battery change. - Vebar® Battery Condition Displays are installed in the charging room:

They inform the operator & maintenance personnel of the issues that have been detected by the Battery Sensors. - Vebar®Gateway is installed in the charging room:

The Gateway provides the wireless RF communication between the Battery Sensors, the Displays, the Remote Web Server, Remote users (LAN/WAN), the Web database and Email server.

Features

- Battery Sensors, Gateway and Info Displays all use industrial RF wireless technology!

- First Available Battery Indication, based on the real SOC, Health and Temperature.

- Continuous and fully automated battery & charger performance checks.

- Sensor records all important parameters

- Automatic upload of logged info to an online database.

- Historical data, key performance info, graphical reports and real time battery status are available.

- Automated notifications:

- on the Battery Sensor via LEDs

- on the local Wireless Displays

- Fully automated Email messaging

- On your computer, in real-time, anywhere in the world (internet needed)

BENEFITS

- Reduces Maintenance & Repair Cost for Batteries & forklifts.

- Detects energy guzzling batteries so you can save BIG on energy.

– 50% savings are no exceptions! – - Reduces battery-related labor, minimizes battery changes and increases efficiency.

- Identifies batteries that need water and detects many other battery issues far in advance, before they become expensive issues. Extends Battery Life.

- Detects when chargers cause damage to batteries by overcharging & overheating.

- Promotes even use of all your batteries, thus minimizing the number of batteries needed.

- Typical ROI is less than 1 year.

NO MORE GUESSING

Your battery vitals are constantly monitored and analyzed by the Vebar Wireless Battery Sensors.

The Sensor reports Alerts to wireless displays, your remote PC and your email*.

The state of health of your batteries is always clear: you are informed the moment a problem or exception is detected.

Historic data is available with the click of a mouse, on-board, on-site and on- line!*

WIRELESS BATTERY ORGANIZING SYSTEM

Vebar battery sensors communicate wireless with the Vebar Gateway*, that sends wireless info to the wireless FIFO displays.

They indicate the Best Available Battery and SOC, promoting the even use of all batteries.

WORLDWIDE ACCESS

With a Vebar network- connected Gateway*, all measurements, alerts and cycle data can be sent to a secure server to ensure lifetime data availability.

Reports are only a mouse click away.

Every battery issue can be confirmed by email to the appropriate mailbox(es).

*Vebar gateway needed.